Manufacturer Rubber Bearing Roller Polyurethane Rubber Coated Roller with Bearings

Company Description ·Over 10 years exporting experience in printing·Specialize in rubber rollers,ceramic anilox roller a;

Basic Info.

| Model NO. | JCTPRINT rubber roller |

| Application | Printing Rubber Roller,Industrial Rubber Roller |

| Color | Red, Black, White, Clear, etc Can Do The Color Bas |

| Base Roll Material | 45 Carbon Steel |

| Custom Made | Provide |

| Rubber Material | NBR,EPDM,Silicone,Polyurethane,Butyl and So on |

| Delivery Date | 10-20 Days |

| Transportation | Railway, Air, Sea, Express |

| Length Range | 50mm-8200mm |

| Configuration of Surface | Rubber Roller |

| Sample Service | Provide |

| Inspection Report | Provide |

| Surface Hardness | 18A~100A |

| Precision | 0.01mm |

| Roll Surface Material | Rubber Roller |

| Transport Package | Wooden Packing |

| Specification | According to customer requirements |

| Trademark | JCTPRINT |

| Origin | China |

| HS Code | 3926909090 |

| Production Capacity | 300PCS/Month |

Product Description

Company Description·Over 10 years exporting experience in printing·Specialize in rubber rollers,ceramic anilox roller and flexo printing cylinders, etc ·All kinds of solutions for printing companies ·Various rubber rollers program·Export to more than 40 countries

Product Description

| Size | Customized according to customer requirements |

| (For offset printing roller, supply drawing stock based on your machine type) | |

| Dimension | 10MM-1500MM,Length:50MM-8200MM |

| Hardness | 18A-100A |

| Tolerance | 0.05mm |

| Temperature | According customers's requirements |

| Color | Red, Black, White, Clear, etc can do the color base on your pantone NO |

| Roll core | stainless steel,45#steel or 20#steel or 5#aluminum seamless pipe |

Provide rubber rollers used in different industries

No matter what industry you are in, what field you apply in, you will find the matching roller in JCTPRINT! Printing Rubber Roller Industrial Rubber Roller Textile Rubber Roller Plastic machinery rubber roller

Our advantage

*Base Roll:We use #45 steel, #201 stainless steel, #304 stainless steel and 5# aluminum seamless pipe as the base roll. And according to the requirements of the customer's drawing, the bottom roller with a reasonable thickness is used.*Rubber:Take imported rubber from Germany or the US and mix them together. The rubber coating technology we use is winding technology. The raw rubber is poured layer by layer on the substrate, and then vulcanized, so that the raw rubber becomes cooked rubber.*Dynamic balancing:Before installing shaft head, we will do dynamic balancing test twice for each rubber roller, which will ensure the using effect.*Hot charging technicals: Adopt hot charging technicals to install the shaft head, and then weld after contraction to ensure the quality of shaft installation. *Quality control Department: Using all-imported laser tester to ensure that the geometric size and the accuracy of the roller can reach 0.01 mm*Packaging: According to the characteristics of the product for different packaging, such as paper tube, wooden box, iron frame and so on.

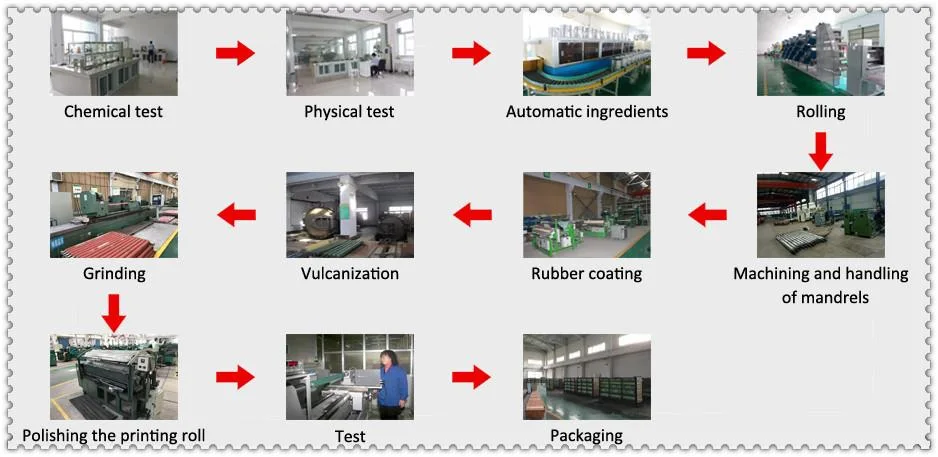

Processing technology

We use the most advanced production technology, which guarantees higher production precision, shorter delivery time and faster production efficiency, achieving maximum reliability.

Our productsJCTPRINT recommends products that best match your equipment.

Our factory

Exhibition

You may also like

Send inquiry

Send now