Hot Forging Aluminum 6061 T6 7075 Forged Motorcycle Spare Parts

Basic Info.

| Surface Treatment | Zinc Plating/Passivation/Polishing/Customized |

| Forging Tolerance | +/-0.1mm |

| Standard | AISI/ASTM/JIS/GB/BS |

| Certification | ISO 9001:2008, IATF16949 |

| Drawing Format | Dwg, Dxf, Iges, Step, Xt, etc. |

| Mold Material | H13.SKD61, Kda1s.Cr12MOV etc. |

| Secondary Service | in-House CNC Machining/Surface Treatment/Welding |

| Transport Package | Protective Bubble Pack+Paper Carton+Wooden Case |

| Specification | Custom metal parts |

| Trademark | N/A |

| Origin | China |

| Production Capacity | 500000pieces/Year |

Product Description

Hot forging aluminum 6061 T6 7075 forged motorcycle spare parts

Our Features:----------------------------------------------------------

19 years industry experience11 years in Euro-market, been serving Top 10 companies in the Railway and gym equipments industries.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

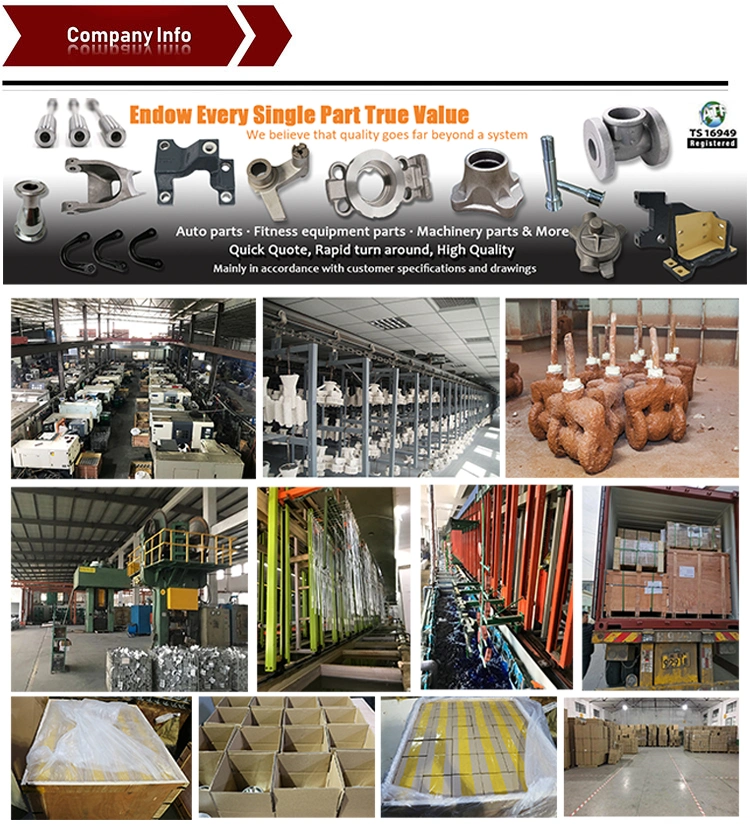

Muyang machinery is a manufacturer with the capability of comprehensive services of casting, forging and machining, committed to the production of customized parts. Since established in 2002 (former Miaosen Machinery Co., Ltd), we've been supplying to the global market for over 15 years, served industries include automotive, railway, gas and oil, medical machinery, construction machinery, gym equipment, etc.

Process | Hot forging, cold forging, die forging with secondary service |

Material | Carbon steel: A36,1045,1035 etc., Alloy steel: 40Cr, 20CrMnTi, 20CrNiMo,42CrMo4 etc., Stainless steel, SS304,SS316 etc. |

Standard | ISO, DIN, ASTM, BS etc. |

Weight | 0.1kg - 20kg (in accordance with product structure) |

Applicable Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc. |

Machining Tolerance | ±0.005mm |

Machined Surface Quality | Ra0.8-Ra3.2 according to customer requirement |

Applicable Heat Treatment | Normalization, Quenching and tempering, Case |

Hardening, Nitriding, Carbon Nitriding, Induction Quenching | |

Applicable Finish Surface Treatment | Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting |

Testing equipment | Supersonic inspection machine, Supersonic flaw detecting machine , Physics and chemical analysis etc. |

Packing | Wooden cases or according to customers' requirement |

MOQ of mass production | 1000-5000pcs ( in accordance with actual condition) |

We promise our clients careful, safe and tight package for exporting!

Standard packing: pearl cotton/bubble bag + carton box + pallet/wooden box

Special packing: custom packaging + wooden box

FAQ:

1. Are you a manufacturer or trading company?We're a manufacturer with self-export rights. 2. What's your main business?Our main business is custom metal parts processed by CNC machining, casting, forging, etc., serving industries including railway, automobile, construction machinery, gym equipment, water gas, and oil.3. Directly get to CONTACT or send your product drawing/inquiries to email, we will reply within 0.5 hours.